SBR Package Sewage Wastewater

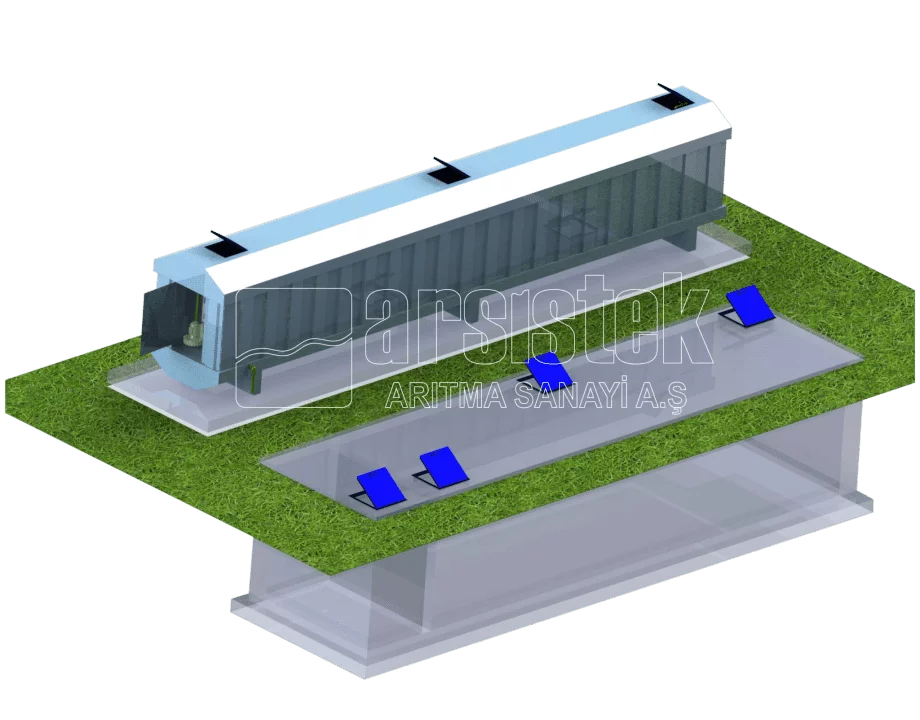

SBR PACKAGE WASTEWATER TREATMENT PLANTS

MODULAR STRUCTURE

Thanks to its modular structure, capacity can be increased by adding package units.

EASE OF OPERATION

They are easy-to-operate systems thanks to the automation system and ground-based operation.

LOWER COSTS

The investment and operating costs of the system are low compared to other treatment processes.

ENERGY EFFICIENCY

The energy power of the pumps and other equipment in the system is selected according to the unit needs.

PACKAGE TREATMENT SYSTEMS !

Arsistek Wastewater Treatment Inc.; It carries out domestic and international turnkey projects from start to finish in its own factory, at all capacities, without being dependent on external sources. In this regard, all mechanical equipment needed by treatment facilities is produced as “Project Specific”.

- Municipalities, Counties and Villages

- Residences and Buildings

- Stadium and Sports Facilities

- Construction Sites and Dormitories

- Universities and Campuses

- Military Facilities

- Prisons and Campuses

- Refugee Campgrounds

- Organized Industrial Zones

- Factories and Industrial Sites

- Student Dormitories and Campuses

- Hotels and Resorts

- Hobby Gardens and Nature Tourism

- Campgrounds

- Villas and Sites SBR Package Treatment

- Slaughterhouses SBR Treatment

- Fruit Juice and Processing Plants

- Dairy Factories, Production Facilities

- Textile Industry Factories

- Fish Processing Facilities

SBR PACKAGE SEWAGE WASTEWATER TREATMENT PLANTS

USINES DE TRAITEMENT DES EAUX USÉES

Package wastewater treatment systems are systems that are applied especially for the treatment of domestic biological waste water. Our units are generally 100 and 1000 people in our factory. package wastewater treatment it is produced in a production period of 7-15 days. Capacities can be added to meet the desired needs. Our company provides full service in many domestic and foreign countries with its factory without being dependent on foreign countries.

Waste water first reaches the “Channel” with manual or automatic cleaning screens. The solids in the wastewater that cannot be dissolved in the water are retained and are removed from the system manually or automatically.

Manual Gratings are generally manufactured as ST37 material and galvanized coating. However, depending on the population and flow rate, “Automatic Mechanical Screen” should be preferred.

The mechanical screen works automatically and automatically transfers the solid materials to the waste bucket.

The waste water, which is purified from solid materials by passing through the screens, reaches the pre-settlement basin. The settleable particles, especially the suspended solids in the waste water, are kept in the settling basin. Thus, the pollution load of the waste water decreases to a certain extent, and as a result, it allows the mechanical equipment throughout the system to operate smoothly.

The solid particles accumulating on the sedimentation basin floor must be removed from the system separately by pulling them with the help of vacuum trucks at certain periods.

Water transferred from the upper level of the preliminary settling pool is collected in the “EQUALIZATION BASIN”. Designed on a project basis, the balancing pool is used to store water.

Wastewater in the balancing pool is sent to the project-based packaged wastewater treatment tank.

With the blower, which is compact in the system, oxygen transfer is provided so that microorganisms can live and reproduce.

Oxygen transfer is provided by the blower, which is compact in the system, for the reproduction of microorganisms. In this way, the wastewater reaches the oxygen richness at a rate. In the control of PLC Automation, the blower becomes passive and the organisms in the waste waters that remain dormant for a certain period of time settle to the bottom and are transmitted to the discharge line by the discharge pump. By making Chlorine dosage on the discharge line, possible escape of bacteria is prevented and odor formation is prevented.